And now for some pretty shocking before and afters (my favorite).

So there you have it, our full kitchen renovation. And yes, I’m super sad that I only got to enjoy it for a month before we moved to Dallas. But it just makes me even more excited for our next renovation. If you have any questions about our kitchen or renovation process feel free to leave a comment below. Or if you are looking to hire someone to tackle your next project, I’m taking on a couple more new clients this fall.

| S O U R C E S |

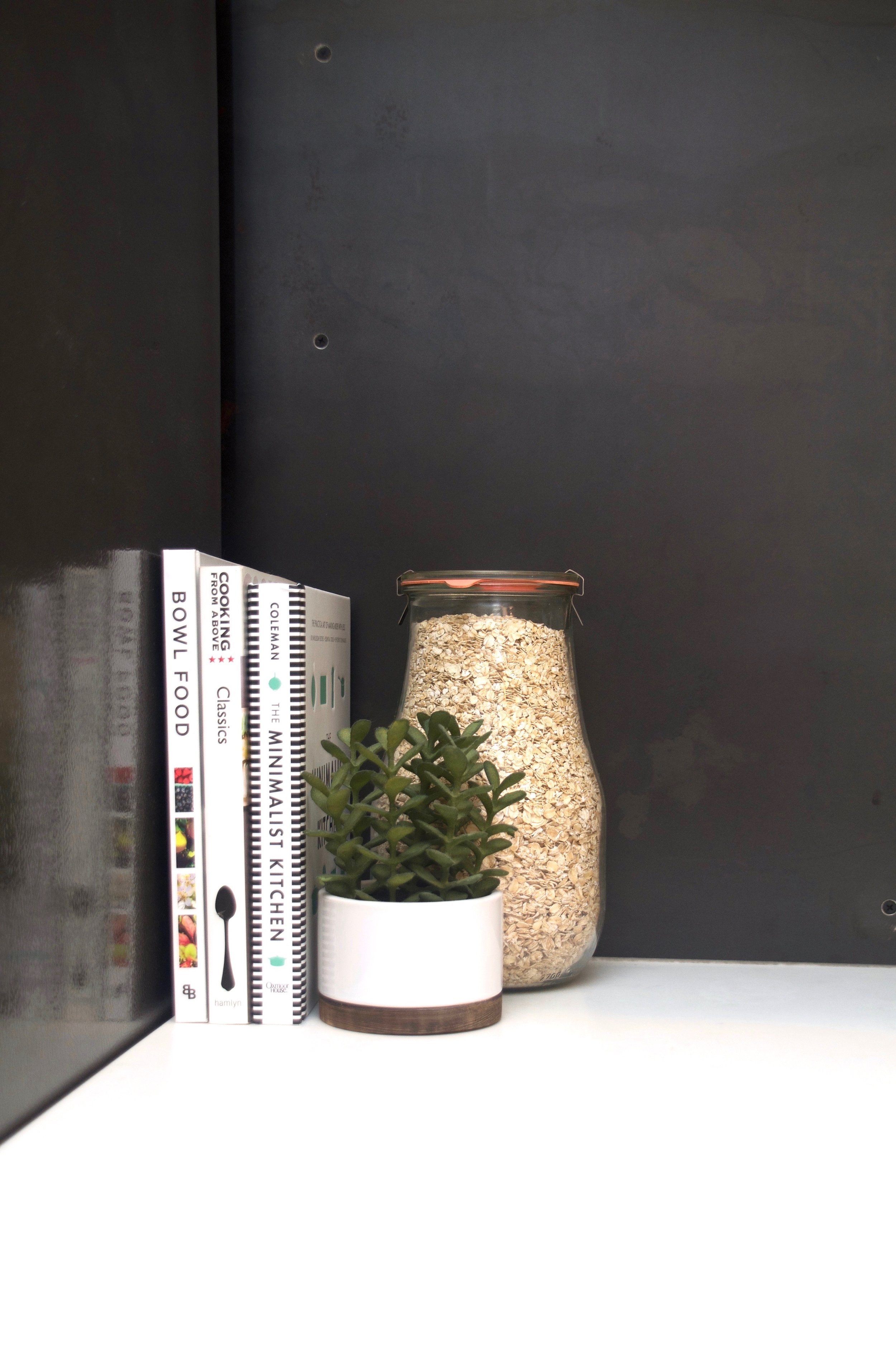

Flooring | Lower Cabinets (via Habitat Restore) | Hardware | Countertops | Tile Backsplash | Faucet | Floating Shelves (custom) | Vent Hood Insert and Liner | Vent Hood Wrap (custom) | Upper Cabinets (custom) | Steel Backsplash (custom) | Barn Light Sconce | Pendant Lights | Can Lights | Island (vintage) | Fridge | Range | Dishwasher | Sink | Bowls + Dishes | Glasses | Tea Glasses | Stainless Steel Bowls | Cutting Board | Straight Canisters | Tapered Canisters | Utensil Holder

Here are all of the posts in case you missed any:

Part III: Lighting Up the Joint

Part V: Our Not So Custom Cabinets

Part VI: Countertops + Hardware